Tel:021-50453207-13

Tel:021-50453207-13 Mr Liu:13370210819

Mr Bao:13611912930

Mr Wang:13621912475

Email:sales@smtrfid.com

Tel:021-50453207-13

Tel:021-50453207-13 1, project background

Early manufacturing, traditional management and methods have been unable to meet the growing social and scientific development. The main problems are: raw materials, energy prices rising labor costs to bring pressure on enterprises to operate; there are lack of scientific and efficient management, uneven division of labor, accuracy is not high. Automotive manufacturers and parts suppliers face greater pressure: on the one hand, they need to continue to reduce costs; on the other hand, they have to ensure that their products in line with the industry's most stringent quality standards.

2, project objectives

1, through the deployment of RFID system, to achieve the entire process of visual management and manufacturing process of distributed control.

2, the whole system includes production line operation management, quality control management, system management, production line resource management functions.

3, in addition to production monitoring control, but also to achieve the sharing of data information and real-time statistics, in order to facilitate the management of production monitoring and scheduling.

3, program features

1, accurate data collection

Through the RFID reader and RFID electronic label communication, can save manual records, can quickly intelligent remote identification of the collected data, and maximize the accuracy of the collected data

2, workshop production management

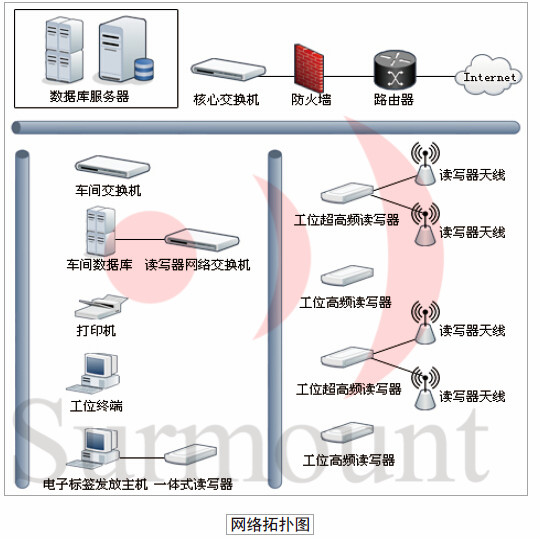

RFID reader through the identification of RFID tags to achieve the entry of field operations information, and the relevant information through the network to the server database.

3, information system management

Through the software design to define some models of production line production and logistics management information system user permissions, executive function and user authorization function, the maintenance of the basic data of each subsystem module public, complete data backup operation.

4, real-time monitoring function

According to the plan and production schedule of production orders, can view real-time understanding of different order quantities and completion, real-time monitoring, transparent production schedule, provide strong support for the implementation and management of project scheduling